Biomass Boilers

Biomass products are abundant and renewable, and in these present days of increasing concerns about global warming, they represent an interesting alternative to fossil fuels. Biomass energy, for the most part, creates no harmful CO2 emissions, is considered carbon neutral, reduces dependency on fossil fuels, and reduces contribution to landfills.

Biomass boilers use thermal conversion (gasification and combustion) to extract the inherent energy in biomass material for heating or producing electricity. Although most biomass products will combust very well, the boilers must be engineered correctly, taking into consideration the combustion characteristics of the fuels, the impact on boiler configuration, and ultimately, operating and maintenance requirements.

Types of fuels that can be used inside a biomass boiler range from woodchips, sawdust, bark, and forestry residuals to agricultural biomass (switchgrass, hemp, sugarcane, bamboo, non-woody biomass).

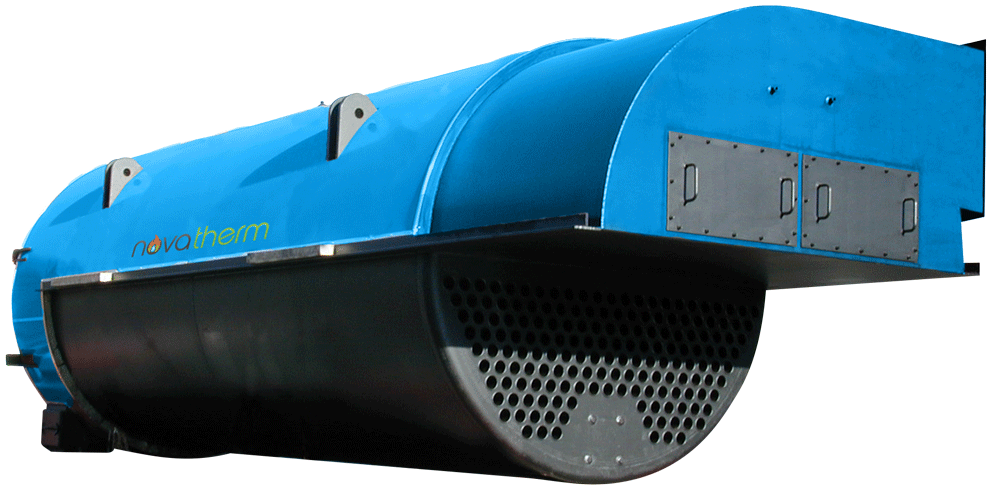

Horizontal Return Tubular (HRT) Boiler

The HRT boiler has a horizontal cylindrical shell containing several horizontal flue tubes, with the fire located directly below the boiler’s shell, usually within a brickwork setting. Gas flows into the HRT boiler from the firebox to the rear of the boiler. It then returns through the tubes to the front, where it is discharged to the breaching and out the stack.

Novatherm’s HRT boilers are designed and engineered for your application and to meet your specific requirements and operating conditions.

Water Leg Boilers

Better fitted for small capacities, Novatherm’s engineering team will design and engineer a unit that meets your specific operating conditions and requirements.