eVoFlex

Water Tube 5-Pass Flexible Boiler

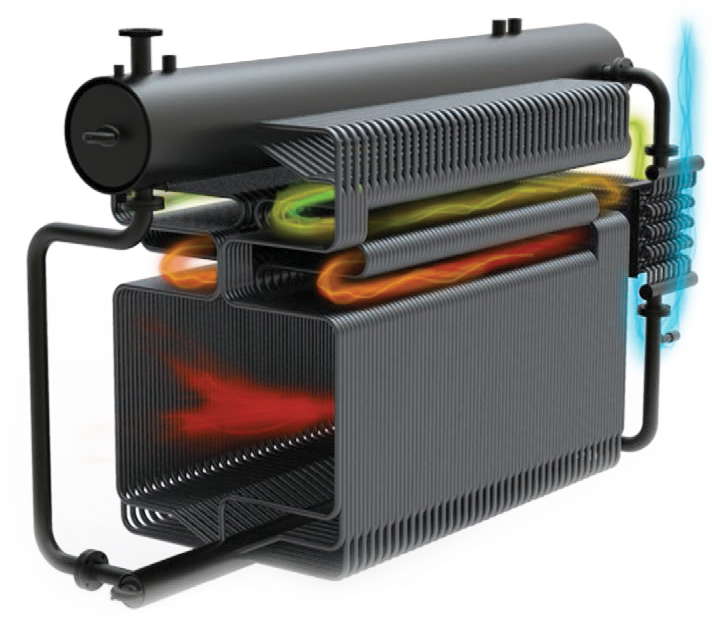

The eVoFlex boiler is the result of the technological evolution of the conventional 5-pass flexible watertube boiler design.

Higher Energy Efficiency

Possessing several patented innovations, eVoFlex boilers provide higher energy efficiency than conventional flexible watertube and firetube boilers. They use less fuel, thus reducing operating costs. To achieve the highest efficiency, the eVoFlex can be supplied with an integrated steaming economizer. This innovation directly reduces installation cost and the need for expensive flow control valve assembly, therefore reducing the typical payback period.

Smaller Footprint and Smaller Access

eVoFlex boilers are ideal when space is limited. They can easily be assembled onsite when access is restricted and without requiring pressure welders. They also require less clearance space for maintenance than an equivalent firetube boiler.

Flexible Boiler

These flexible water tube boilers are versatile and perfectly suited for many applications. They can be configured to generate hot water or steam at very high pressure, or to heat thermal fluid with a large temperature differential.

Unlike firetube boilers, which must be kept hot when on standby, flexible watertube boilers can generate steam quickly on demand.

Standard Equipment

Our boilers come equipped with all the controls required to ensure a safe and automatic operation. Novatherm only uses components and burners that are well known for their high quality and availability. Replacement parts are available throughout North America.

Our boilers can be fired with gas (natural gas or propane) or light oil, or a combination of both fuels. In addition, we can supply advanced burner controls to allow an increased range of modulation. Low NOx burners, compliant with the most stringent environmental regulations, are also available.

Low Water Content Water Tube Boiler

The DeltaFlex and eVoFlex flexible watertube boilers are available with a low water content design to comply with some state or provincial laws for stationary engineers.

Ontario’s TSSA has certified this boiler that uses less than 75 imperial gallons of water in operation for up to 300 HP with the integrated economizer. This boiler offers the best fuel-to-steam efficiency and does not require operators.

These boilers can also be supplied with a circulating pump to comply with the coil type design and provide the same operator exclusion while offering higher efficiency and steam quality than a coil type boiler.

When firetube boilers are not the favoured type of boiler due to the stationery engineer’s regulation constraints, a flexible watertube boiler usually offers a much cheaper alternative.

Stationary engineers usually account for the second-highest boiler room operating costs, right after the fuel costs. Choosing the right type of boiler for your application is, therefore, very important.

Technical Information

| Capacity: | From 2 MMBTU/hr (60 HP) to 33.5 MMBTU/hr (1000 HP). Higher capacities are available. |

| Application: | Low pressure steam (≤ 15 psi) High pressure steam (≤ 150 psi) Very high pressure steam (> 150 psi) Superheated steam (< 750°F) Hot water, low temperature (≤ 250°F) Hot water, high temperature (> 250°F) Thermal fluid |

| Fuel: | Natural gas, propane, light oil |

| Efficiency: | From 80% (standard mode) to over 85% (high efficiency mode) fuel to steam efficiency |

| Emissions: | Meets current local regulatory limits |

| Gas Passes: | 5 (standard mode) or 6 (high-efficiency mode) |