DeOxy

Deaerator System

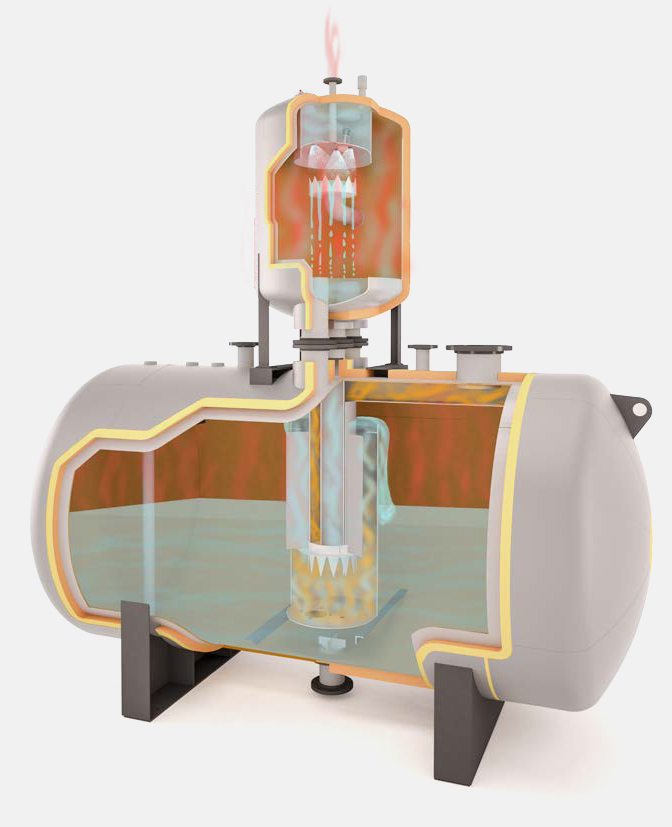

The DeOxy deaerator removes dissolved gases such as oxygen in the boiler feedwater. It allows substantial savings in the use of chemicals and in the number of blowdowns required. A deaerator will prevent the corrosion in the system and in the boiler.

Oxygen is the main cause of corrosion found in steam systems. With the presence of carbon dioxide in water, the pH will be highly acidic and corrosion will occur. This minimizes the life expectancy of boiler room equipment.

Performance

The increase of water temperature to saturation and atomization into fine droplets using spray valves, allows dissolved gases to be released from the water and then vented outside the system. The removal of gas dissolved in water reduces the concentration of oxygen to less than 0.005 cc/litre in the feed water.

Construction

The deaerator head, where gas separation takes place, is made of stainless steel to extend equipment life expectancy. The deaerated water is then transferred to the reservoir which is made of carbon steel per the ASME standard for pressurized vessels.

Since the system operates at temperatures near saturation, the DeOxy deaerator is supplied with a support of sufficient height to ensure high enough available NPSH to prevent pump cavitation.

Controls

The system is fully automated and operates autonomously. A modulating valve controls the water level in the reservoir to ensure stable operation. A pressure modulating valve is used to maintain constant pressure in the deaerator to ensure a stable temperature. A control panel is also provided including magnetic starters, push buttons, and switches for the pumping system.

Standard Equipment

Novatherm only uses components and manufacturers that are well known for their high quality and availability. Replacement parts are available throughout North America.

Technical Information

| Capacity: | From 10,000 lb/hr to 300,000 lb/hr. Larger units are available on demand. |

| Pressure: | 5 psig operating pressure |

| Temperature: | 227°F operating temperature |

| Voltage: | 575/3/60 or other voltages are available as an option |

| Material: | Standard carbon steel, stainless steel 304 for head and internals |

| Insulation: | Insulation and cladding are offered as an option |